MAKESafe Power Tool Brake Emergency Stop System, with Pre-Wired Interlock Pigtail, 1.5 HP, 120V 1-Phase, without Power Connectors - PTBV120P1-MCFC-INT

Brand: MAKESafe Tools- SKU:

- PTBV120P1-MCFC-INT

- ID:

- 579654

| HP | 1.5 HP |

| Voltage | 120V |

| Phase | 1-Phase |

| Power Connectors | No Connectors |

| Config Code | INT |

MAKESafe Power Tool Brake Emergency Stop System, with Pre-Wired Interlock Pigtail,

1.5 HP, 120V 1-Phase, without Power Connectors - PTB-V120-P1-MC-FC-INT

A plug-and-play safety system for industrial machinery that provides an ANSI-compliant emergency stop, motor braking, and accidental restart protection.

This one device provides three distinct safety features that help to prevent injuries and avoid OSHA citations. These features are:

- Category-1 Emergency Stop Button

- Unintentional Restart Prevention

- Motor Braking

This standard product configuration includes everything you need to protect industrial machines like bench grinders, band saws, disc sanders, surface grinders, lathes, and other industrial equipment. If you questions about compatibility, please review the compatibility guide in the specifications section or contact us.

ALL-IN-ONE FEATURES

E-Stop - ANSI-compliant emergency stop for easy activation.

Motor Braking - Brings your machine to a complete stop in seconds!

Restart Protection - Prevents injuries caused by accidental restarts.

INSTALLS IN MINUTES

- Installation is simple. You just plug it in and your machinery is protected. The whole process takes just a few minutes and requires no electrical expertise.

BENEFITS

Keep Workers Safe - Integrated emergency stop system prevents injuries and protects against three distinct types of hazard.

Comply with OSHA - MAKESafe identified the most common machine violations and designed our products to bring your machinery into compliance.

Quick & Easy Install - Safety system installs in minutes, requires no specialized expertise to install, and can be can be used with any induction-motor based machinery.

Increase Efficiency - These products improve the everyday operation and usability of machinery with easy access to controls and by eliminating annoying coasting and extended wind-down times.

Each standard package includes:

- The Power Tool Brake

- 3-Button Control Panel

- Product Manual, Adjustment Tool, & Adjustment Hole Plugs

Control Panel Details:

The compact control panels are made of durable ABS plastic and maintains a UL94 V-0 rating. The start and stop buttons are custom manufactured by OTTO Controls in Illinois and are designed for long-term durability with solid aluminum bezels, a no-slip surface finish, and a strong tactile response. The latching emergency-stop button is Swiss-manufactured by EAO. The entire control panel is water, dust, and oil resistant and rated for millions of on/off cycles.

The control panel connects easily to the power tool brake via an industrial M12 twist connector. The 5 ft (1.5m) cable extension and dual mounting flanges allows the control panel to be mounted easily in a convenient location.

Power Tool Brake Details:

The Power Tool Brake is constructed of durable ABS plastic and maintains a UL94 V-0 rating. With a 5′ (1.5m) power extension and dual mounting flanges, it is designed to be easily mounted in an out-of-the-way location. Basic calibration can be achieved via two access holes in the side of the enclosure and rubber plugs are included to seal these holes once installation is complete.

Installation:

Installation takes less than five minutes for most customers and includes the following steps:

- Plug your machine into the power tool brake.

- Cover your existing machine switch and mount the control panel.

- Calibrating the braking power.

Detailed instructions are available in the Product Manual.

Approvals:

- UL508: Industrial Control Devices (E114885)

- CSA #14-13: Industrial Control Equipment (E114885)

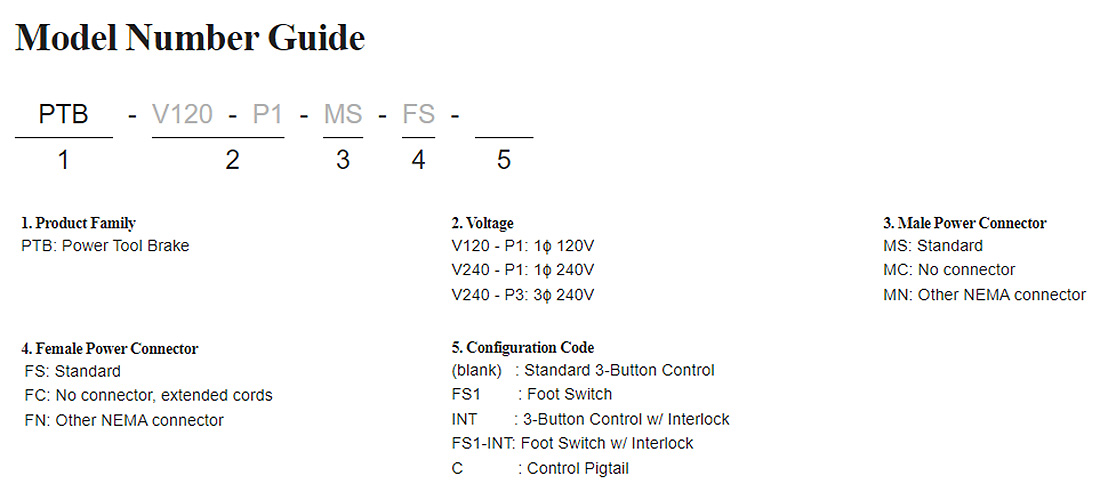

Alternate Configurations:

These products are also offered with multiple configuration options and accessories, including:

- Control Accessories: foot switches, additional e-stop buttons, guard interlocks, attachments for automation

- Frequency: products can also be configured for 50hz operation

- Plugs: products can be fitted at the factory with any plug type you require

Specifications:

| Model | PTB-V120-P1 | PTB-V240-P1 | PTB-V240-P3 |

| Rated Input Voltage | 120 VAC, 1 PH, 60 Hz (50 Hz options available) |

240 VAC, 1 PH, 60 Hz (50 Hz options available) |

240 VAC, 3 PH, 60 Hz (50 Hz options available) |

| Rated Horsepower (UL508) | 1.5 HP | 3.0 HP | 5.0 HP |

| Rated Current (UL508) | 15A | 15A | 15A |

| Approvals | UL508: Industrial Control Devices CSA #14-13: Industrial Control Equipment LISTING NUMBER: E114885 |

||

| Dimensions (main enclosure only) | 7.25” L x 5.0” W x 2.3” H (185 mm x 127 mm x 57 mm) |

||

| Dimensions (std. control panel) | 3.0” x 2.0” x 0.9” in. (76.20 mm x 50.80 mm x 22.86 mm) |

||

| Weight (main enclosure) | 3 lbs. (1.4 kg) | 3 lbs. (1.4 kg) | 3.3 lbs. (1.5 kg) |

| Rated Output Voltage (normal operation) | 120 VAC | 240 VAC | 240 VAC |

| Rated Output Voltage (during braking) | 15 - 90 VDC | 30 - 180 VDC | 30 - 240 VDC |

| Standard Connector Type | NEMA 5-15 (custom and international options available) | NEMA 6-15 (custom and international options available) | NEMA L15-20 (custom and international options available) |

View the Control Options

See all versions of the MAKESafe Power Tool Brake Emergency Stop System

For more info, visit www.p65warnings.ca.gov.