26th Feb 2021

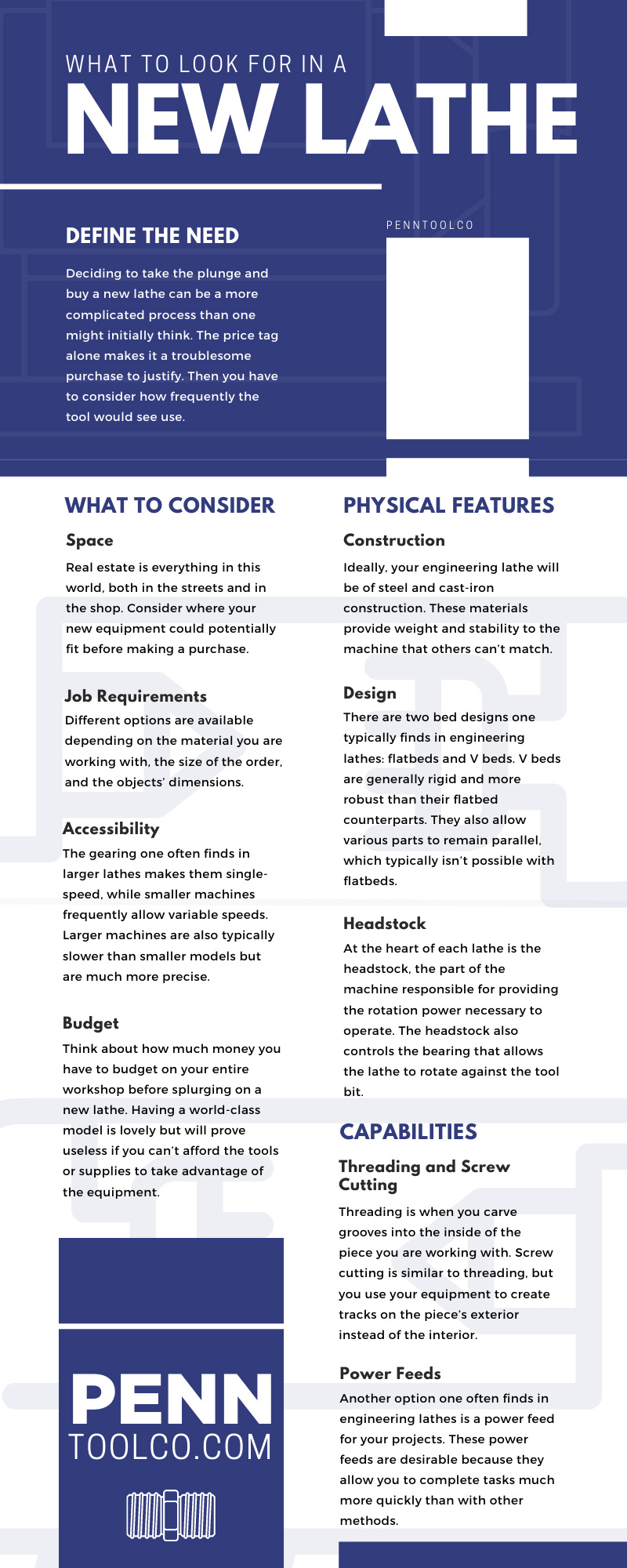

What To Look for in a New Lathe

What To Look for in a New Lathe

Buying a new lathe for your workshop is challenging for many professionals. While you may be able to make do with other tools in the past, this changes once volume becomes a concern. A lathe speeds up the production process in your machine shop and ensures each product is up to standard.

But finding the right lathe for your business can be a challenge. There are many different factors about your company, workshop, and output to consider before you can decide what product to purchase. Because so many buyers don’t know what to look for in a new lathe, we’ve compiled everything you need to know before you make your decision.

Define the Need

Deciding to take the plunge and buy a new lathe can be a more complicated process than one might initially think. The price tag alone makes it a troublesome purchase to justify. Then you have to consider how frequently the tool would see use.

But the fact that you’re even considering the purchase is justification enough to look into the details of what you can accomplish with it. A lathe is one of the most versatile tools you can purchase because you can use it to turn, bore, grind, face, and thread objects at speeds impossible to replicate by hand. Buying one in your shop is an excellent investment so long as the use justifies the purchase.

What To Consider

There are many things about your current situation you must consider before purchasing a lathe. Write down a list of your wants and needs from the new tool. A list facilitates later comparison between models to find the perfect fit. Here are a few of the factors you should be considering.

Space

Real estate is everything in this world, both in the streets and in the shop. Consider where your new equipment could potentially fit before making a purchase. The more space you have available, the bigger the machine you’ll want. A larger size helps establish a better foundation, reducing bounces and other fluctuations.

Job Requirements

Another factor to consider in the lathe you buy will be the requirements for the job. Different options are available depending on the material you are working with, the size of the order, and the objects’ dimensions.

Accessibility

The gearing one often finds in larger lathes makes them single-speed, while smaller machines frequently allow variable speeds. Larger machines are also typically slower than smaller models but are much more precise. New engineers may benefit from trying a variable-speed model at first to get a feel for a lathe’s full capabilities.

Budget

Think about how much money you have to budget on your entire workshop before splurging on a new lathe. Having a world-class model is lovely but will prove useless if you can’t afford the tools or supplies to take advantage of the equipment. Aside from the lathe and supplies, you’ll also need to consider other factors, such as transportation of the machine and customer support options after the purchase.

Physical Features

When it comes to your new lathe’s physical attributes, there are varying levels of quality to consider before you make a purchase. Here is more information on what to look for in a new lathe’s design elements.

Construction

Ideally, your engineering lathe will be of steel and cast-iron construction. These materials provide weight and stability to the machine that others can’t match. Added stability from the extra weight prevents vibrations from the motor and the force applied by the spinning object.

Design

There are two bed designs one typically finds in engineering lathes: flatbeds and V beds. V beds are generally rigid and more robust than their flatbed counterparts. They also allow various parts to remain parallel, which typically isn’t possible with flatbeds.

Headstock

At the heart of each lathe is the headstock, the part of the machine responsible for providing the rotation power necessary to operate. The headstock also controls the bearing that allows the lathe to rotate against the tool bit. For metalworking, this generally requires at least two horsepower.

Capabilities

The final set of information to consider is what each machine can do in comparison to the others. This stage is where you take out your list of features that you need in a lathe and start matching them. Obviously, the objective is to find as many of your “wants” as possible for a reasonable price. Here are some of the features to look for when comparing new engineering lathes.

Threading and Screw Cutting

Threading and screw cutting are two features many professionals look for when buying a new lathe. Threading is when you carve grooves into the inside of the piece you are working with. Screw cutting is similar to threading, but you use your equipment to create tracks on the piece’s exterior instead of the interior. This method allows the two components to twist into each other, securing a tight connection.

Power Feeds

Another option one often finds in engineering lathes is a power feed for your projects. These power feeds are desirable because they allow you to complete tasks much more quickly than with other methods. Not only that, but the product will be better and more consistent, thanks to the steady mechanical speed.

Variable Speeds

One option present in some models is the ability to change the speed at which your machine operates. Control over the spin rate allows the operator to work on pieces that would cause excessive vibrations in larger machines because of imbalance issues. As mentioned above, a larger lathe is less likely to have these variable speeds.

One of the most important factors to remember is that you get what you paid for when you are shopping for new equipment. Check out the professional team at Penn Tool Co. if you are looking for a new wood or metal lathe for sale. We have a huge selection to meet all your engineering needs. In business since 1968, Penn Tool Co. is a proud provider of high-quality precision measuring equipment, metalworking machines, and other workshop tools.