Posted by Penn Tool Co., Inc on 16th Jul 2021

Broken Tap Fixed Right

Broken Tap Fixed Right

Are you ever working on a project with internal threads, and you're starting to work on the hole, and suddenly, a piece breaks off? The tap is broken inside the hole and seems about impossible to get out and continue the project in a timely manner. No, it’s not impossible, but it can be timely, however it’s not always successful. Every machinist must follow precautions and have the knowledge to use the proper tools to remove a tap to avoid an unsuccessful outcome.

First, why did it break?

There are many factors as to why the tap broke in the first place. The tap may be out of alignment with the hole, the hole may be too small, a tapping error, as well as many other reasons.

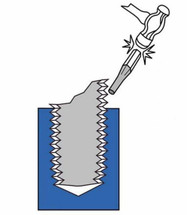

How to Remove Breakage

●Electric Discharge Machining (EDM)

○Most reliable method, however, is least practice, whereas most small machine shops don’t have access this machinery

●Manually smash the tap

○Cost-effective, but least effective

●Use an Extractor

○Specifically designed to remove broken taps

○However, access to a screw extractor is costly

●Use an Omegadrill

●TIG Welding

○Suggest using a 309 or a 312 rod

How to prevent breakage

●You must focus and chose the best hole size

●When given an opportunity, use form taps

●Use purpose-made tapping lubricants to reduce the friction between your cutting tool and the project to make the cutting process faster and more efficient, while also improving surface finishes and extending tool life.