ACU-RITE Edge Finders

ACU-RITE is proud to offer two probes that can connect and provide edge-finding functions on some of its most popular products, including on the 200S and 300S digital readouts and the MILLPWR G2 two- or three-axis control and three-axis readout system.

Accommodating a wide range of jobs, ACU-RITE’s offers the KT 130 Triggering Edge Finder that can be used for both conductive and non-conductive materials and a KT 3-D Electronic Edge Finder useful for conductive material.

Used in conjunction with ACU-RITE’s readouts or control system, these edge finders accommodate a wide range of jobs, decrease setup times and ensure precise, repeatable positioning.

With the KT 130 Edge Finder, the stylus is deflected when it contacts the workpiece, and the edge finder sends a triggering signal over the connecting cable to the 200S or 300S digital readout or the MILLPWR G2.

This probe, mounted in the spindle, zeros on contact with a conductive workpiece, increasing operator speed and accuracy when establishing datum (workpiece zero). The 3-D, spring-loaded probe records the located edge, even if over-travel should occur.

Functions on ACU-RITE MILLPWR G2 Control Systems

- Locate datum (workpiece zero)

- Locate spindle center-relative to workpiece

- Teach Positions

Functions on ACU-RITE READOUT Systems

All of the G2 functions plus...

- Measure inside and outside workpiece dimensions

- Center, measure or find the midpoint of holes/circular parts

The KT 3-D Electronic Edge Finder probe is for use with the 200S and the 300S series readouts or the MILLPWR G2.

The probe is mounted in the spindle and automatically zeros on contact with a conductive work piece. This increases operator speed and accuracy when establishing datum (or work piece zero.) The 3-D spring loaded probe records the located edge, even if over-travel should occur.

When used with an ACU-RITE readout, the following probing soft key functions are available:

- Workpiece edge as datum: EDGE soft key

- Centerline between two workpiece edges

- CENTER LINE soft key

- Center of a hole or cylinder

- CIRCLE CENTER soft key

In all probing functions, 200S takes into account the probe’s entered tip diameter. During probing functions, with an electronic, or grounding edge finder, the display freezes with the location of the edge, centerline, or circle center.

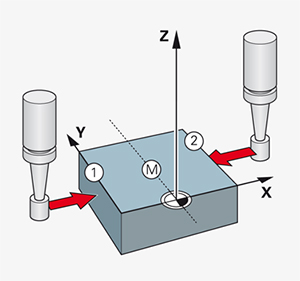

Readout Edge Finding Example

|

Setting centerline between two workpiece edges as datum 0 is offered as a default value for the coordinate. Enter the desired coordinate for the workpiece edge. For this example Y = 0.0, set the coordinate as a datum for this workpiece.

- Press the ENTER hard key

- The position of the centerline M is determined by probing the edges 1, and 2

- The centerline is parallel to the Y axis

- Desired coordinate of the centerline: X = 0.0

- Press the DATUM soft key

- Press the DOWN arrow key to select the item you need

- Press the PROBE soft key

- Probe the 1st edge X

- Move the edge finder toward workpiece edge 1 until the LEDs in the edge finder light up

- Probe the 2nd edge in X Move the edge finder toward workpiece edge 2 until the LEDs in the edge finder light up

- The distance between the edges is displayed on the message box

- Retract the edge finder from the workpiece

- Enter the value for X

- Enter coordinate (X = 0.0), and transfer coordinate as datum for the centerline

- Press the ENTER hard key

For more info, visit www.p65warnings.ca.gov.

| Item Number | Description | Price | Quantity |

|---|---|---|---|

| KT130 | KT130 Triggering Edge Finder | $ 1,795.00 | |

| KT3D | KT3D Electronic Edge Finder | $ 2,095.00 | |

| 2002508 | Connecting Cable for MILLPWR II | $ 110.00 | |

| 108547601 | Connecting Cable for MILLPWR G2 | $ 79.95 |